Marine kryogenes Rückschlagventil (Flanschtyp) für LNG-Systeme

Merkmale:

| Parameter | Wert |

|---|---|

| Ventiltyp | Kryogenes Rückschlagventil |

| Verbindungstyp | Flansch |

| PN | 2, 3, 4, 6, 8, 10, 12, 14, 16, 18, 20, 24 Zoll |

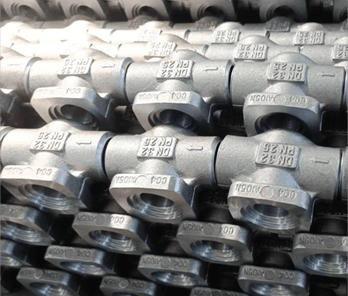

| Material | Stahlguss |

| Struktur | Schwingrückschlagventil |

| Druckklasse | Klasse 150 |

| Höhe (h) | 5,7 Zoll (145 mm) bis 27,4 Zoll (697 mm) |

| Gewicht (Gew.) | 16 kg (2 Zoll) bis 1398 kg (24 Zoll) |

| Anwendungen | Flüssigerdgas (LNG), Schifffahrt, Offshore |

| Temperaturbeständigkeit | Kryogenik |

Detailliste

Produktdetails

Anwendung

Langlebig und zuverlässig in rauen Meeresumgebungen

Das kryogene Rückschlagventil (Flanschausführung) für LNG-Systeme ist speziell für die rauen Bedingungen in maritimen Anwendungen entwickelt. Es besteht aus hochfesten Werkstoffen und gewährleistet so Langlebigkeit und zuverlässige Funktion auch unter extremen Bedingungen, wie beispielsweise auf Offshore-Plattformen und LNG-Schiffen. Das Ventil bietet hervorragende Verschleiß- und Korrosionsbeständigkeit und garantiert damit den reibungslosen Betrieb Ihres LNG-Systems selbst unter anspruchsvollsten Bedingungen.

Fortschrittliches Kryotechnik-Design für LNG-Anwendungen

Dieses speziell für kryogene Systeme entwickelte Ventil eignet sich ideal zur Steuerung des Durchflusses von verflüssigtem Erdgas (LNG) bei extrem niedrigen Temperaturen. Seine fortschrittliche Konstruktion gewährleistet einen stabilen Betrieb in kalten Umgebungen und steigert so die Effizienz und Zuverlässigkeit von LNG-Speicher-, Transport- und Verteilungssystemen. Ob an LNG-Terminals oder auf Seeschiffen – dieses Ventil bietet optimale Durchflussregelung für kryogene Flüssigkeiten.

Auslaufsicherer und sicherer Betrieb

Sicherheit hat bei LNG-Systemen höchste Priorität, und dieses Ventil gewährleistet einen leckagefreien Betrieb auch unter hohem Druck. Ein robuster Dichtungsmechanismus verhindert Rückfluss und sorgt für einen sicheren und effizienten LNG-Fluss. Dadurch werden Leckagerisiken minimiert und die Systemzuverlässigkeit insgesamt verbessert. Das Ventil ist unerlässlich für den sicheren und kontinuierlichen Betrieb von LNG-Pipelines, Terminals und Schiffen.

Kompakt und einfach in bestehende Systeme zu integrieren

Dank seiner kompakten Bauweise lässt sich das Ventil problemlos in bestehende LNG-Systeme integrieren und ist somit eine komfortable Lösung für Neuinstallationen und Nachrüstungen. Das benutzerfreundliche Design spart wertvolle Zeit und Aufwand bei der Einrichtung, reduziert die Installationskomplexität und gewährleistet eine nahtlose Integration in Ihre maritime Infrastruktur. Durch seine geringen Abmessungen kann das Ventil auch in beengten Räumen installiert werden, ohne die Leistung zu beeinträchtigen.

Erfüllt die Anforderungen an Hochdruck- und Tieftemperaturtoleranz für LNG-Anwendungen

Das kryogene Rückschlagventil (Flanschausführung) für LNG-Systeme ist für den zuverlässigen Betrieb unter Hochdruck- und Tieftemperaturbedingungen ausgelegt und gewährleistet optimale Funktionalität in anspruchsvollen LNG-Anwendungen. Es eignet sich ideal für LNG-Systeme, die Langlebigkeit und Leistung sowohl in kryogenen als auch in Hochdruckumgebungen erfordern. Das Ventil bietet Ihnen die Gewissheit, dass es seine Leistung auch unter strengsten Betriebsbedingungen beibehält.

Wartungsfreundliches Design für den Dauerbetrieb

Das kryogene Rückschlagventil (Flanschausführung) für LNG-Systeme ist wartungsfreundlich konstruiert. Seine einfache Bauweise reduziert den Reparaturaufwand und minimiert Ausfallzeiten. Die Langlebigkeit und der geringe Wartungsaufwand des Ventils gewährleisten einen unterbrechungsfreien Betrieb Ihres LNG-Systems, senken die Wartungskosten und verbessern die Betriebseffizienz.

Verpackung & Lieferung

Wir verwenden eine Durchsteckverpackung, und das Ventil wird in einem PP-Beutel verpackt, um die Produktsicherheit bestmöglich zu gewährleisten. Wir bieten Versand per See- und Luftfracht an und können die Produkte an jeden von Ihnen gewünschten Hafen liefern.

Nachricht jetzt senden

Vorteile

-

Hersteller

Tsunny Valves konzentriert sich auf die Konstruktion und Produktion von Ventilen. Das Unternehmen verfügt über 7 Gießlinien und mehr als 40 Werkstätten zur Kontrolle des Gieß-, Bearbeitungs-, Montage- und Verpackungsprozesses.

-

Warum wir?

① Direktverkauf ab Werk, wettbewerbsfähiger Preis ② Qualitätsgarantie – 100%-geprüft vor dem Verkauf ③ Schnelle Lieferung innerhalb von ca. 30 Tagen für 1 bis 500 Stück

-

Wir können OEM-Produkte herstellen.

Besitzen eine eigene, unabhängige Marke und sind gut in der OEM-Produktion. Unsere Produkte entsprechen den Normen ANSI/API, DIN, JIS/KS, BS, NF und Russland.