Válvula de retención criogénica marina (tipo brida) para sistemas de GNL

Características:

| Parámetro | Valor |

|---|---|

| Tipo de válvula | Válvula de retención criogénica |

| Tipo de conexión | Brida |

| PN | 2, 3, 4, 6, 8, 10, 12, 14, 16, 18, 20, 24 pulgadas |

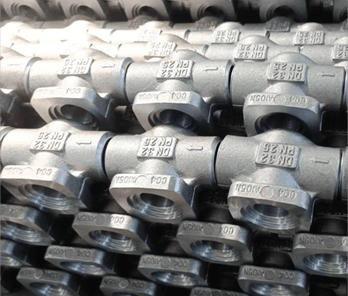

| Material | Acero fundido |

| Estructura | Válvula de retención oscilante |

| Clase de presión | Clase 150 |

| Altura (h) | 5,7 pulgadas (145 mm) a 27,4 pulgadas (697 mm) |

| Peso (wt) | 16 kg (2 pulgadas) a 1398 kg (24 pulgadas) |

| Aplicaciones | Gas natural licuado (GNL), marino, offshore |

| Capacidad de temperatura | criogénico |

Lista de detalles

Detalles de producto

Solicitud

Durable y confiable en entornos marinos hostiles

La válvula de retención criogénica marina (tipo brida) para sistemas de GNL está diseñada para soportar las duras condiciones de las aplicaciones marinas. Está diseñada con materiales de alta resistencia para garantizar una larga durabilidad y un rendimiento fiable en entornos extremos, como plataformas marinas y buques metaneros. Ofrece una excelente resistencia al desgaste y a la corrosión, lo que garantiza el correcto funcionamiento de su sistema de GNL incluso en las condiciones más adversas.

Diseño criogénico avanzado para aplicaciones de GNL

Diseñada específicamente para sistemas criogénicos, esta válvula es ideal para controlar el flujo de gas natural licuado (GNL) a temperaturas extremadamente bajas. Su diseño avanzado garantiza un funcionamiento estable en entornos fríos, mejorando así la eficiencia y la fiabilidad de los sistemas de almacenamiento, transporte y distribución de GNL. Tanto si trabaja en terminales de GNL como en buques, esta válvula proporciona una gestión óptima del flujo de fluidos criogénicos.

Operación segura y a prueba de fugas

La seguridad es una prioridad absoluta al manipular sistemas de GNL, y esta válvula garantiza un funcionamiento a prueba de fugas a alta presión. Un robusto mecanismo de sellado evita el reflujo y garantiza un flujo de GNL seguro y eficiente, minimizando el riesgo de fugas y mejorando la fiabilidad general del sistema. Esta válvula es crucial para mantener un funcionamiento seguro y continuo en tuberías, terminales y buques de GNL.

Compacto y fácil de integrar en sistemas existentes

La estructura compacta de la válvula facilita su instalación en sistemas de GNL existentes, lo que la convierte en una solución práctica tanto para nuevas instalaciones como para renovaciones. Su diseño intuitivo ahorra tiempo y esfuerzo durante la instalación, reduciendo la complejidad y garantizando una integración perfecta en su infraestructura marina. Su pequeño tamaño permite su instalación en espacios reducidos sin comprometer su rendimiento.

Cumple con los requisitos de tolerancia criogénica y de alta presión para operaciones de GNL

La válvula de retención criogénica marina (tipo brida) para sistemas de GNL está diseñada para funcionar de forma fiable en condiciones de alta presión y baja temperatura, garantizando un funcionamiento óptimo en aplicaciones exigentes de GNL. Es ideal para sistemas de GNL que requieren durabilidad y rendimiento tanto en entornos criogénicos como de alta presión. La válvula proporciona tranquilidad, sabiendo que mantendrá su rendimiento en condiciones de operación rigurosas.

Diseño de fácil mantenimiento para un funcionamiento continuo

La válvula de retención criogénica marina (tipo brida) para sistemas de GNL está diseñada para facilitar su mantenimiento. Su estructura simple reduce la necesidad de reparaciones frecuentes y minimiza el tiempo de inactividad. Su durabilidad y bajo mantenimiento garantizan que su sistema de GNL funcione de forma continua con mínimas interrupciones, lo que reduce los costos de mantenimiento y mejora la eficiencia operativa.

Embalaje y Entrega

Usamos empaques de orificio pasante y la válvula se envuelve en una bolsa de PP para garantizar la seguridad del producto en la mayor medida posible. Apoyamos el envío por mar y por aire, y los productos también se pueden enviar a cualquier puerto que especifique.

enviar mensaje ahora

Ventajas

-

Fabricante

Las válvulas Tsunny se centran en el diseño y la producción de válvulas. Tiene 7 líneas de fundición y más de 40 talleres para controlar el proceso de fundición, mecanizado, ensamblaje y empaque.

-

Porque nosotros

①Venta directa de fábrica, precio competitivo ②Garantía de calidad: prueba 100% antes de la venta ③Entrega rápida En aproximadamente 30 días de 1 a 500 piezas

-

Podemos hacer OEM

Tenemos nuestra propia marca independiente y somos buenos en la producción OEM. Nuestros productos involucran estándares ANSI/API、DIN、JIS/KS、BS、NF、RUSIA.