Marine Cryogenic Check Valve (Flange Type) for LNG Systems

Features:

| Parameter | Value |

|---|---|

| Valve Type | Cryogenic Check Valve |

| Connection Type | Flange |

| PN | 2, 3, 4, 6, 8, 10, 12, 14, 16, 18, 20, 24 inches |

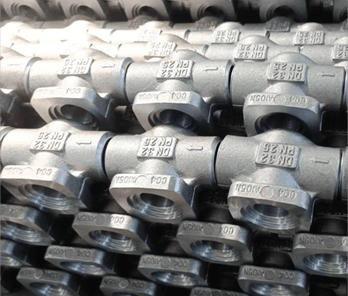

| Material | Cast Steel |

| Structure | Swing Check Valve |

| Pressure Class | Class 150 |

| Height (h) | 5.7 inches (145 mm) to 27.4 inches (697 mm) |

| Weight (wt) | 16 kg (2 inches) to 1398 kg (24 inches) |

| Applications | Liquefied Natural Gas (LNG), Marine, Offshore |

| Temperature Capability | Cryogenic |

Details list

Product Details

Application

Durable and Reliable in Harsh Marine Environments

The marine cryogenic check valve (flange type) for LNG systems is engineered to withstand the harsh conditions of marine applications. It is designed with high-strength materials to ensure long-term durability and reliable performance in extreme environments, including offshore platforms and LNG vessels. The valve offers excellent wear and corrosion resistance, guaranteeing that your LNG system operates smoothly even under the most challenging conditions.

Advanced Cryogenic Design for LNG Applications

Specifically designed for cryogenic systems, this valve is ideal for controlling the flow of liquefied natural gas (LNG) at extremely low temperatures. Its advanced design ensures stable operation in cold environments, thereby enhancing the overall efficiency and reliability of LNG storage, transportation, and distribution systems. Whether you are working at LNG terminals or marine vessels, this valve provides optimal flow management for cryogenic fluids.

Leak-Proof and Safe Operation

Safety is a top priority when handling LNG systems, and this valve ensures leak-proof operation under high pressure. A robust sealing mechanism prevents backflow and ensures the safe and efficient flow of LNG, minimizing leakage risks and improving overall system reliability. The valve is crucial for maintaining safe, continuous operation in LNG pipelines, terminals, and marine vessels.

Compact and Easy to Integrate into Existing Systems

The valve’s compact structure allows for easy installation in existing LNG systems, making it a convenient solution for both new installations and retrofits. Its user-friendly design helps save valuable time and effort during setup, reducing installation complexity and ensuring seamless integration into your marine infrastructure. The valve’s small size ensures it can be installed in tight spaces without compromising performance.

Meets High-Pressure and Cryogenic Tolerance Requirements for LNG Operations

The marine cryogenic check valve (flange type) for LNG systems is designed to perform reliably under high-pressure and low-temperature conditions, ensuring optimal functionality in demanding LNG applications. It is perfectly suited for LNG systems that require durability and performance in both cryogenic and high-pressure environments. The valve provides peace of mind, knowing it will maintain performance under stringent operating conditions.

Maintenance-Friendly Design for Continuous Operation

The marine cryogenic check valve (flange type) for LNG systems is designed for easy maintenance. Its simple structure reduces the need for frequent repairs and minimizes downtime. The valve’s durability and low maintenance requirements ensure that your LNG system can operate continuously with minimal interruptions, lowering maintenance costs and improving operational efficiency.

Packing & Delivery

We use through-hole packaging, and the valve will be wrapped in a PP bag to ensure the safety of the product to the greatest extent. We support shipping by sea and by air, and the products can also be shipped to any port you specify.

send message now

Advantages

-

Manufacturer

Tsunny valves focus on valves design and production.Have 7 casting lines and more than 40 workshops to control casting, machining, assembly and packing process.

-

Why us

①Factory direct sale , competitive price ②Quality guarantee – 100% testing before sale ③Fast delivery Within about 30 days of 1 to 500 pieces

-

We can do OEM

Have own independent Brand & Good at OEM production.Our products involve ANSI/API、DIN、JIS/KS、BS、NF、RUSSIA standards.