Vanne de régulation à brides

Caractéristiques:

- Actionneur à piston simple effet de 150 mm de course (L6540N) avec une force de 25 120 N, position de sécurité “ NC ”, pression d'alimentation minimale de 3,5 bar.

- Logiciel intégré de diagnostic pour la surveillance et le contrôle.

- Filtre-réducteur 1/2″ NPT (67AFR-04-LT) avec bouchon de vidange pour l'évacuation des condensats.

- Amplificateur de volume avec filtre en polyéthylène fritté à faible bruit, 1/2″ NPT, fonctionne de -55°C à +60°C.

- Système fiable et économe en énergie pour les tâches d'automatisation exigeantes.

Article Valeur Pression nominale 4,0 MPa Test de coquille 6,0 MPa Test d'emballage 4,4 MPa Test d'étanchéité 0,35 MPa Température de fonctionnement -46°C ~ 300°C Moyen approprié WOG

Liste détaillée

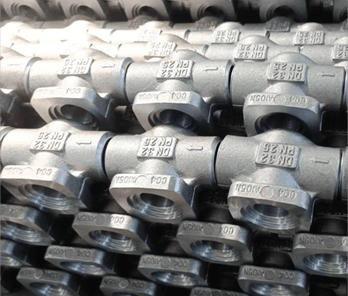

Détails du produit

Liste des pièces

|

Non. |

Nom de la pièce |

Qté |

Matériel |

| 1 | Corps | 1 | LCB |

| 2 | Joint de siège | 1 | SS304+Graphite |

| 3 | Siège | 1 | 304HT+STL |

| 4 | Cage | 1 | 304HT |

| 5 | Prise | 1 | 304+HT+STL |

| 6 | Anneau de piston | 1 | SS316 |

| 7 | Joint de capot | 1 | SS304+Graphite |

| 8 | Bonnet | 1 | LCB |

| 9 | Boulon de capot | 1s | L7 |

| 10 | Écrou de chapeau | 1s | 7 |

| 11 | Tige | 1 | 17-4PH |

| 12 | Emballage | 1 | Graphite |

| 13 | Glande | 1 | 304 |

| 14 | Bride de presse-étoupe | 1 | LCB |

| 15 | Boulon de presse-étoupe | 2 | L7 |

| 16 | Écrou de gland | 2 | 7 |

| 17 | Actionneur | 1 | Assemblée |

Exigences techniques

|

Article |

Spécification |

|

Norme de conception |

ASME B16.34-2009 |

|

Connexion finale |

Connexion finale |

|

Face à face / De bout en bout |

Fabricant |

|

Norme de fuite |

ANSI B16.104-IV |

|

Norme matérielle |

ASTM A352-2009 |

|

Calibre pression-température |

Valeurs nominales de pression et de température |

Application

Présentation du produit

Notre gamme peut être conçue sur mesure pour répondre à vos besoins spécifiques. La structure, les matériaux et les fonctionnalités sont optimisés pour s'adapter à votre processus. Certifiés ISO 9001, nous mettons en œuvre des méthodes systématiques pour garantir une qualité optimale. Vous bénéficiez ainsi d'une fiabilité et d'une étanchéité exceptionnelles tout au long de la durée de vie de votre équipement.

Exigences techniques

Vanne complètement ouverte :

· Une pression différentielle trop importante et une faible pression en aval peuvent endommager la vanne par cavitation.

· Pour l'éviter, faites référence à la pression différentielle en deux étapes ou plus en installant et en connectant directement deux vannes de régulation ou plus en tandem.

Emballage et livraison

Nous utilisons un emballage traversant et la vanne est conditionnée dans un sachet en polypropylène afin de garantir une protection optimale du produit. Nous proposons des expéditions par voie maritime et aérienne, et les produits peuvent être livrés à tout port de votre choix.

Envoyer un message maintenant

Avantages

-

Fabricant

Tsunny Valves se concentre sur la conception et la production de vannes. L'entreprise dispose de 7 lignes de fonderie et de plus de 40 ateliers pour contrôler les processus de fonderie, d'usinage, d'assemblage et d'emballage.

-

Pourquoi nous

① Vente directe d'usine, prix compétitif ② Garantie de qualité – Test 100% avant vente ③ Livraison rapide sous 30 jours environ pour les commandes de 1 à 500 pièces

-

Nous pouvons réaliser des prestations OEM.

Nous possédons notre propre marque indépendante et sommes performants en production OEM. Nos produits sont conformes aux normes ANSI/API, DIN, JIS/KS, BS, NF et russes.